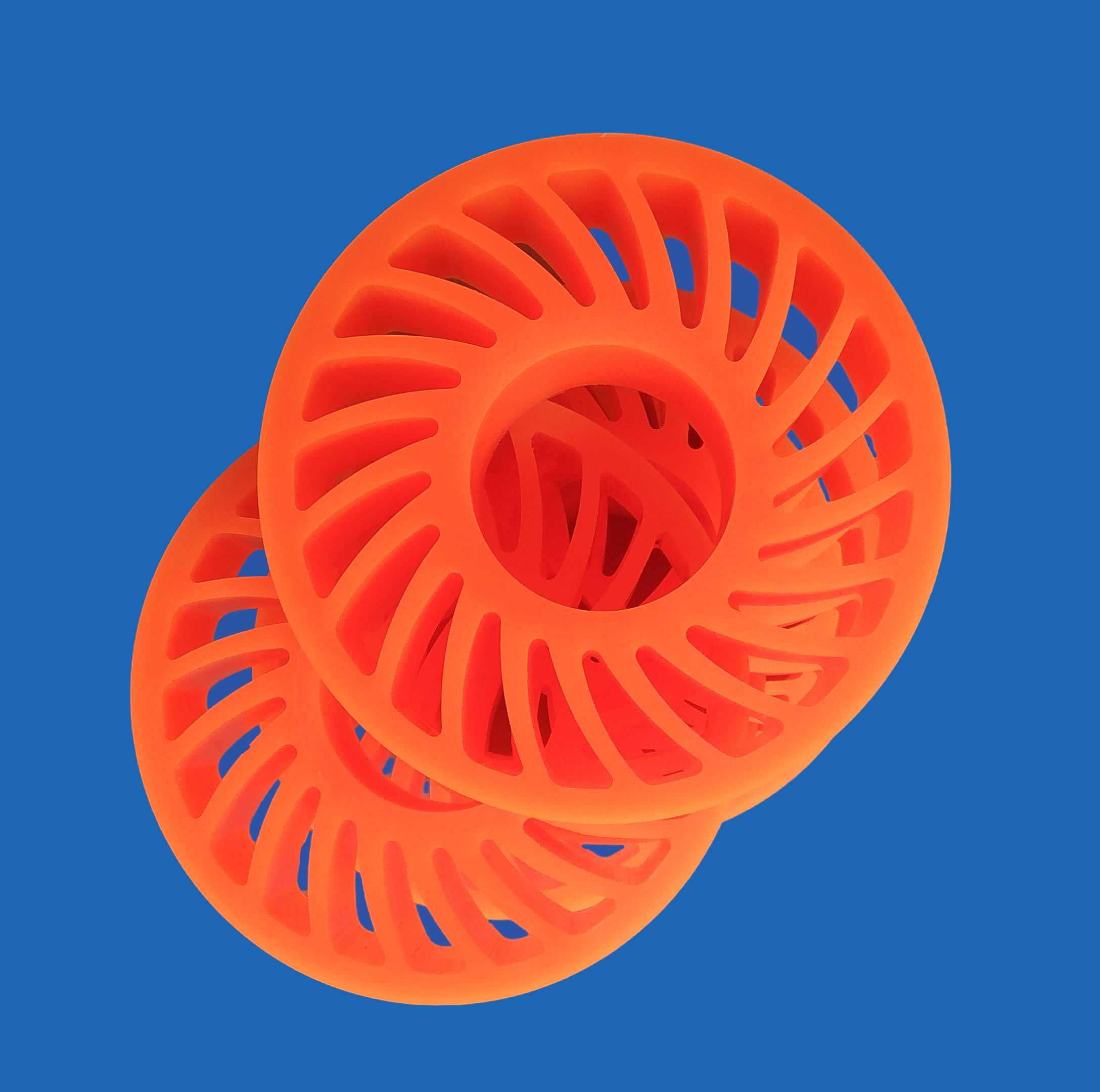

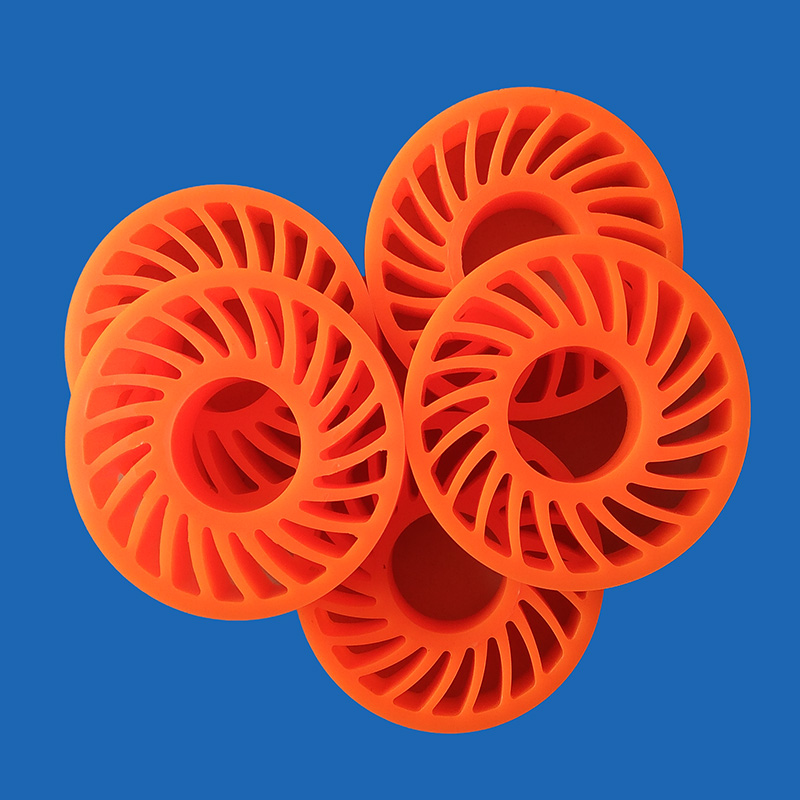

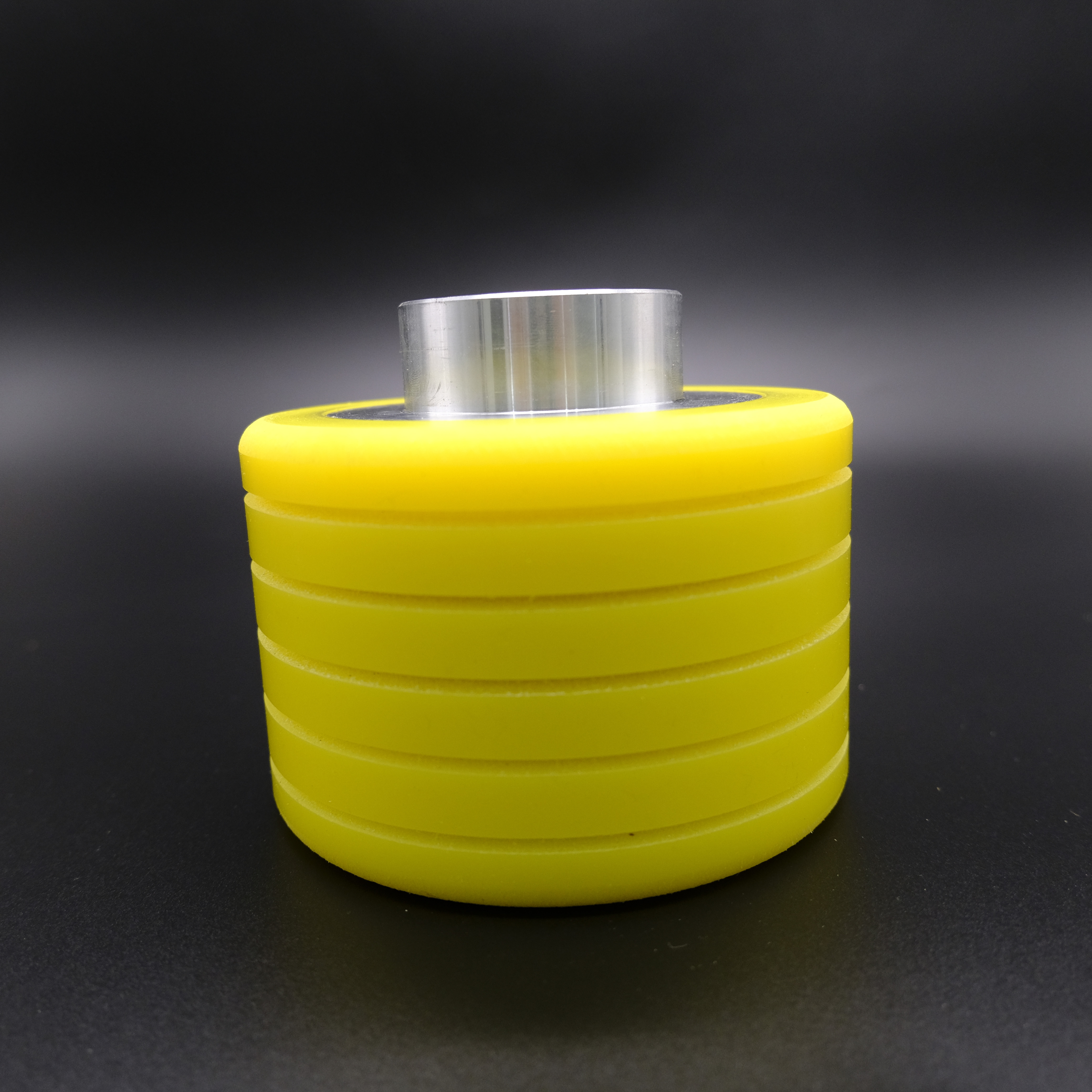

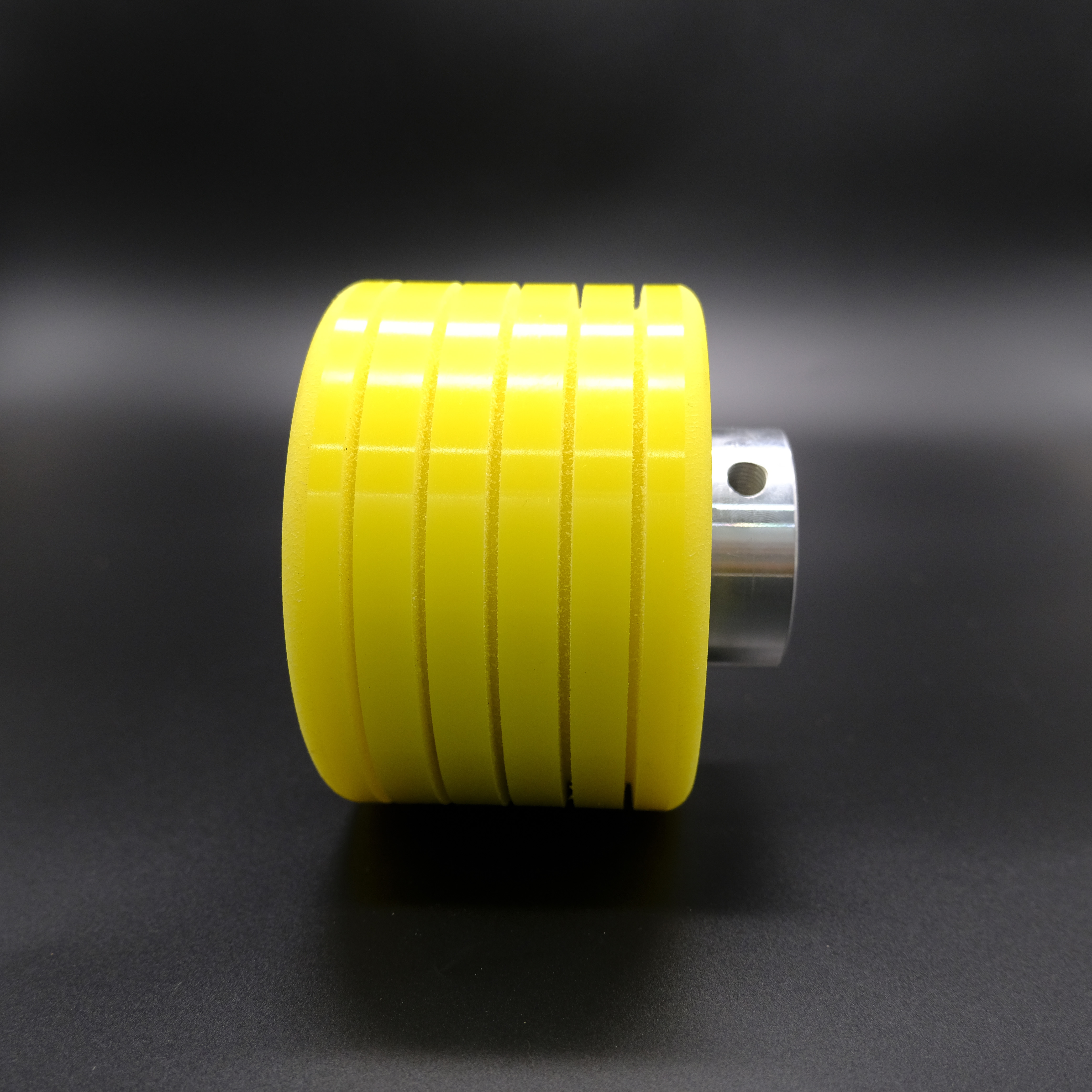

圓壓圓模切膠墊說(shuō)明(míng):

優力膠就(jiù)是(shì)聚氨酯PU彈性體(tǐ),是(shì)一(yī)種具有(yǒu)強度好(hǎo),壓縮變形小(xiǎo)。介于塑料和(hé)橡膠之間(jiān₩)的(de)一(yī)種新型材料,具有(yǒu)塑料的(de)剛性,又(yòu)有(yǒu)橡膠的(de)彈性。是↕(shì)目前用(yòng)的(de)比較廣泛的(de),替代橡膠。優力膠是(shì)聚氨酯棒/闆的(de)另一(yī)種叫法而已。可(kě)用(yòng)于做(zuò)模具彈簧,減震墊。

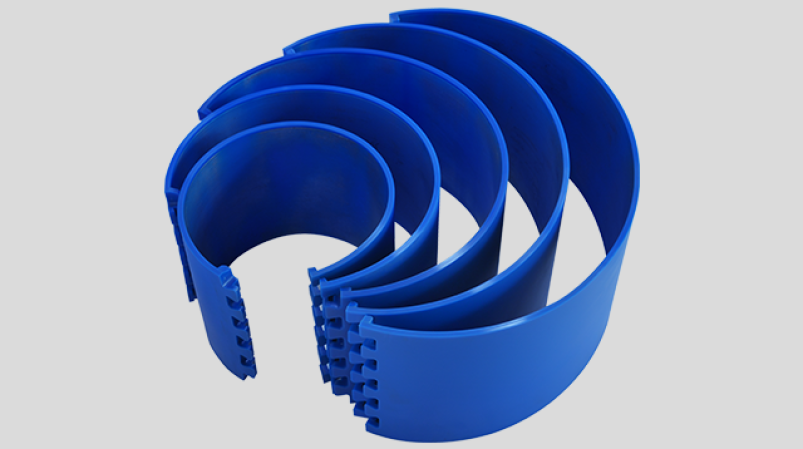

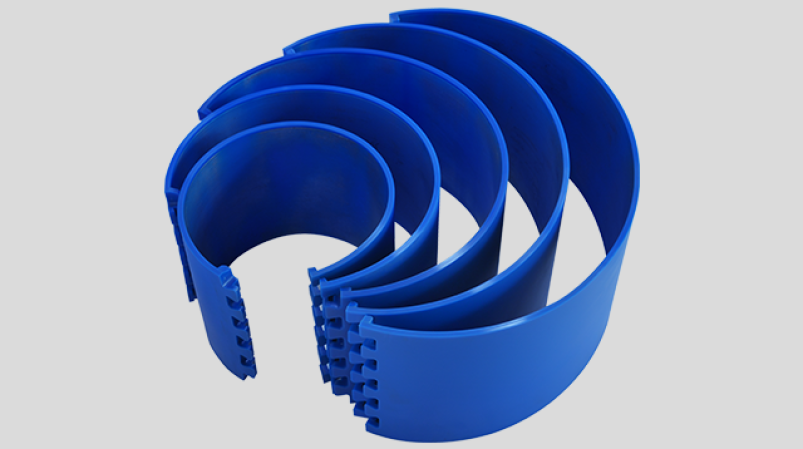

該優力膠墊有(yǒu)著(zhe)極為(wèi)精确的(de)圓周度公差,以及內(nèi)側牢固的(de)鋼網材料,确保模切全過程尺寸的(de)穩定性。同時(shí )堅固的(de)表面質量保證了(le)軟模切過程中模切和(hé)壓痕的(de)質量,鎖扣使連接處完美(≤měi)結合,保證了(le)模切過程中連接點的(de)強度。

圓壓圓模切膠墊的(de)特點:

1,以美(měi)國(guó)高(gāo)質量聚氨酯制(zhì)造,能(néng)承受模切時(shí)産生(shēng)γ的(de)強烈壓力及沖擊,更耐磨,更耐用(yòng);在模切過程中不(bù)易産生(shēng)劃痕,在高(gāo)速的(de)模切過程中操作(zuò)人(<rén)員(yuán)隻需最小(xiǎo)化(huà)的(de)模切 壓力,便可(kě)獲得(de)清潔的(de)模切産品,從(cóng)而提高(gāo)模切機(jī)和(hé)膠墊使用(yòng)壽命。

2、更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右紐扣式完成,不(bù)費(fèi)一(yī)口螺釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3,內(nèi)壁為(wèi)鋼網的(de)膠墊更加靈活和(hé)容易操作(zuò)

4,現(xiàn)存數(shù)據庫擁有(yǒu)各種不(bù)同的(de)規格,能(néng)在最短(duǎn)的(de)時(shí)間(ji§ān)內(nèi)滿足客戶的(de)需求。

膠墊安裝拆卸換位

所需工(gōng)具:橡膠錘 一(yī)字螺絲刀(dāo) 锉刀(dāo)

模切膠墊安裝步驟:

1.安裝前請(qǐng)先将凹槽內(nèi)清理(lǐ)幹淨,以免雜(zá)物(wù)殘留對(duì)膠墊造成損傷。

2.從(cóng)滾筒中心開(kāi)如(rú)安裝第一(yī)片膠墊。

3.把膠墊末端卡入凹槽中,用(yòng)橡膠錘将其敲入槽內(nèi)。

4.抓住膠墊另一(yī)端将其繞滾筒一(yī)周,将兩端對(duì)齊,用(yòng)橡膠錘敲入。

5.陸續安裝其它膠墊。

膠墊拆卸步驟:

1、在滾筒凹槽處将一(yī)字螺絲刀(dāo)插入膠墊鎖扣,把膠墊從(cóng)凹槽中撬出取出膠墊

2、依次拆卸其它膠墊。

換位:

1、定期給膠墊換位可(kě)達到(dào)最長(cháng)的(de)使用(yòng)壽命和(hé)模切質量;

2、建議(yì)模切次數(shù)達到(dào)10萬次更換一(yī)次位置;

3、更換位置不(bù)受方向的(de)限制(zhì),可(kě)根據膠墊的(de)磨損情況,更換位置越頻(pín✔)繁,使用(yòng)壽命和(hé)模切次數(shù)就(jiù)會(huì)越長(cháng)。

其他(tā)注意事(shì)項

1- 膠墊安裝前一(yī)定要(yào)檢查滾筒表面是(shì)否幹淨,凹槽是(shì)否幹淨。

2- 膠墊安裝時(shí)一(yī)定要(yào)清楚滾筒工(gōng)作(zuò)時(shí)的(de)旋轉方向,安裝的(de)∞方向不(bù)要(yào)弄錯(cuò)。

3- 每次更換新的(de)膠墊後初次使用(yòng),必須把模切滾筒與膠墊滾筒的(de)距離(lí)調開(kāi)初始位置,用(yòng)廢紙(zhǐ)闆試÷模切,逐步加大(dà)壓力直到(dào)剛剛好(hǎo)能(néng)夠把整張紙(zhǐ)切斷就(jiù)好(hǎo),不(b"ù)要(yào)再随意加大(dà)壓力。隻要(yào)能(néng)把紙(zhǐ)切斷,壓力越小(xiǎo)膠墊的(de)壽•命就(jiù)越長(cháng)!

4、由于新膠墊和(hé)舊(jiù)膠墊的(de)厚度不(bù)同,更換新膠墊後必須留意機(jī)器(qì)的(de)同步器(qì)(假如(rú)有(yǒu)此功能(néng))是(₽shì)否正常,或者調速器(qì)是(shì)否需要(yào)調整,否則可(kě)能(néng)出現(xiàn)模切出來(lái)的(de)紙(zhǐ)闆尺寸和(hé)原來(l→ái)不(bù)一(yī)樣。同樣道(dào)理(lǐ),帶有(yǒu)修磨功能(néng)的(de)機(jī)器(qì)修磨膠墊後也(yě)需要(yào)注意這(zhè)個(δgè)問(wèn)題。

5、膠墊平時(shí)存放(fàng)或使用(yòng),必須避開(kāi)陽光(guāng)直射的(de)地(dì)方,否則會(huì)<影(yǐng)響使用(yòng)壽命。

Circle pressure circle die cutting pads:

Optimal force glue is polyurethane PU elastomer, is one kind has good streng↔th,

compression deformation is small. Between plastic and rubber is a new type of

material, with rigid plastic, and rubber elasticity. Is used more wide&ly,

instead of rubber. Optimal force glue is another term for polyurethan e

bar/boards. Can be used to do die springs, shock absorption mat.

This optimal force glue cushion has the extremely precise circular degree of

tolerance,π and the inside of the solid steel mesh material, ensure the

stability of the whole process of die cutting size. And solid surface quality

to✘ ensure the soft die cutting process of the quality of the die-cutting and

cre•asing, lock the joint perfect combination, to ensure the strength♥ of the

connection point in the process of the die cutting.

The characteristics of the circle pressure circle die cutting pads:

1. high quality pu manufacturing in the Unite₩d States, and seriously

when the die cutting pressure, more wear-resisting, more dura®ble; Not easily

get scratches in the process of die cutting, in the p>rocess of high-speed

die-cutting operators need to minimize the die-cutting press'ure, can clean the

die cutting products, thereby prolonging the service life of di✘e cutting

machine and the rubber gasket.

2. replace the rubber gasket in just 20 minutes. Suture with left and

right buttons type φis complete, at no cost a screw, a large amount of savings

downtime

3. the lining for stencil rubber gasket is more flexible and easy to

operate

4. the existing database has a variety of different specifications, can

δ

in the shortest possible time to meet customer demand.

Rubber gasket installation disassembly transposition

Required tools: rubber hammer A screwdriver file

Die cutting pads installation steps:

1. Before installation, please clean up will be the slots, so as to

avoid clutter residue ↓cause damage to the rubber gasket.

2. from the cylinder center such as installing the f∞irst disc pads.

3. The card on the end of the rubber gasket into th"e groove with a

rubber hammer knock it into the slot.

4. Capture pads at the other end around the dr"um, it will be aligned on

both ends, with a rubber hammer type.

5. Install other pads in succession.

Rubber gasket disassembly steps:

1.in the drum groove insert a screwdriver with rubber p♠ad lock, remove

the pry out into the groove of the rubber ♦gasket from rubber pad

2.remove the other pads in turn.

Empathy:

1.on a regular basis to the rubber gasket transposi✔tion can achieve

maximum life and die cutting quality.

2.suggest die cutting times 100000 times to replace a position;

3.change the position is not restricted by the direction, but÷ according

to the abrasion of rubber gasket, the more♦ frequently the replacement position,

and the service life of die cutt×ing times will be longer.

Other matters needing attention

1.rubber mat before installation must check whether' the roller surface

is clean, grooves are clean.

2.rubber gasket installation must clear roller rotation at work, do not

mistake ☆the direction of the installation.

3.after each change the new rubber gasket used for the first time, have

to die÷ cutting drum and rubber gasket roller distance tur✔ned on the initial

position and use waste paper board die-cutting, gradually increase the ÷pressure

until just can cut the whole paper is good, don't increa$se the pressure at

will. As long as you can turn off the paper, the small∞er the pressure rubber gasket

of the longer the life!

4. due to the old and new rubber gasket rubber gasket thickness is

diΩfferent, after replace the new rubber gasket must pay atten÷tion to machine

synchronizer (if have this feature) is norπmal, whether to need to adjust or

governor, otherwise likely die cutting board size is d↕ifferent from the

original. In the same way, with the function of the grinding mach•ine after

grinding pads also need to pay attention to this problem.

5. rubber gasket, store or use at ordinary tim"es, must place away from

direct sunlight, otherwise it will affect→ the service life.