-

模切膠墊

圓壓圓模切膠墊說(shuō)明(míng)

優力膠(聚氨酯PU彈性體(tǐ))簡介

優力膠是(shì)一(yī)種介于塑料和(hé)橡膠之間(jiān)的(de)新型材料,具有(yǒu)高(gāo)強度、低™(dī)壓縮變形、塑料的(de)剛性和(hé)橡膠的(de)彈性。它廣泛用(yòng)于替代橡膠,适用(yòng)于模具彈←簧、減震墊等場(chǎng)景。優力膠是(shì)聚氨酯棒/闆的(de)另一(yī)種稱呼。

産品特點

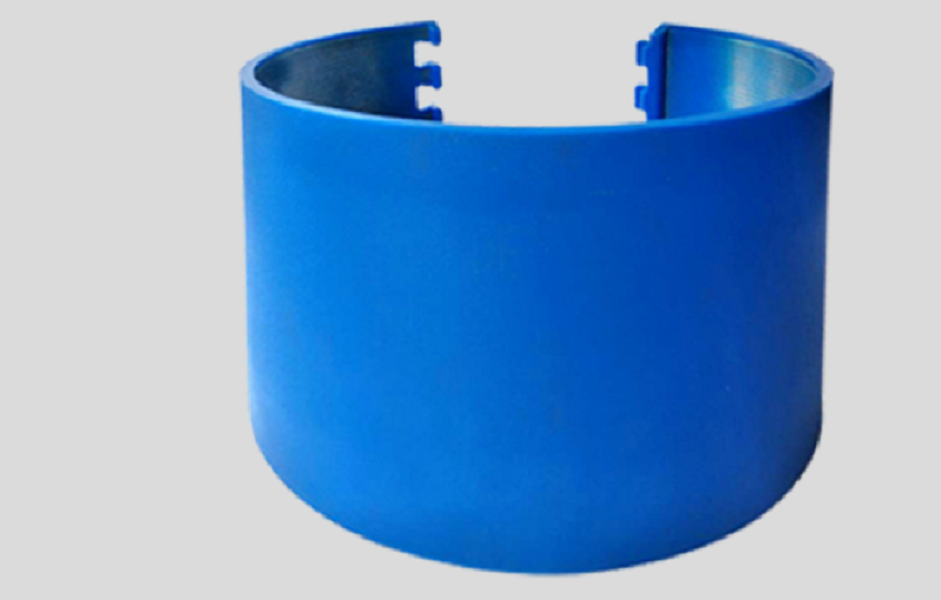

1. 高(gāo)精度圓周度公差:膠墊具有(yǒu)極高(gāo)的(de)圓周度精度,确保模切過程中尺寸的(de)穩定性。

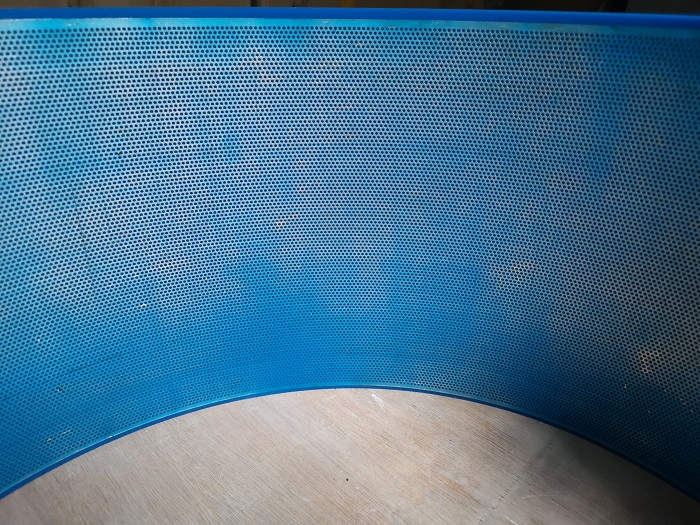

2. 內(nèi)側鋼網結構:內(nèi)置牢固的(de)鋼網材料,增強膠墊的(de)耐用(yòng)性和(hé)操作(zuò) 靈活性。

3. 堅固表面質量:保證軟模切過程中模切和(hé)壓痕的(de)高(gāo)質量。

4. 鎖扣設計(jì):連接處采用(yòng)鎖扣設計(jì),确保模切過程中連接點的(de)強度。

圓壓圓模切膠墊的(de)特點

1. 高(gāo)質量材料

- 采用(yòng)美(měi)國(guó)優質聚氨酯制(zhì)造,能(néng)夠承受模切時(shí)的(de₽)高(gāo)壓和(hé)沖擊,耐磨耐用(yòng)。

- 在高(gāo)速模切過程中不(bù)易産生(shēng)劃痕,操作(zuò)人(rén)員(yuán)隻需®最小(xiǎo)壓力即可(kě)獲得(de)清潔的(de)模切産品,延長(cháng)模切機(jī)和(hé)膠墊的(de)使用(yòng)壽命。

2. 快(kuài)速更換

- 更換膠墊僅需20分(fēn)鐘(zhōng),采用(yòng)左右紐扣式縫合,無需螺釘,大(dà)幅減少(shǎo)停機(jī)時(shí)間(≤jiān)。

3. 靈活操作(zuò)

- 內(nèi)壁鋼網設計(jì)使膠墊更加靈活,易于操作(zuò)。

4. 多(duō)樣化(huà)規格

- 現(xiàn)有(yǒu)數(shù)據庫涵蓋多(duō)種規格,能(néng)夠快(kuài)速滿足客戶需π求。

膠墊安裝、拆卸與換位

所需工(gōng)具

- 橡膠錘

- 一(yī)字螺絲刀(dāo)

- 锉刀(dāo)

安裝步驟

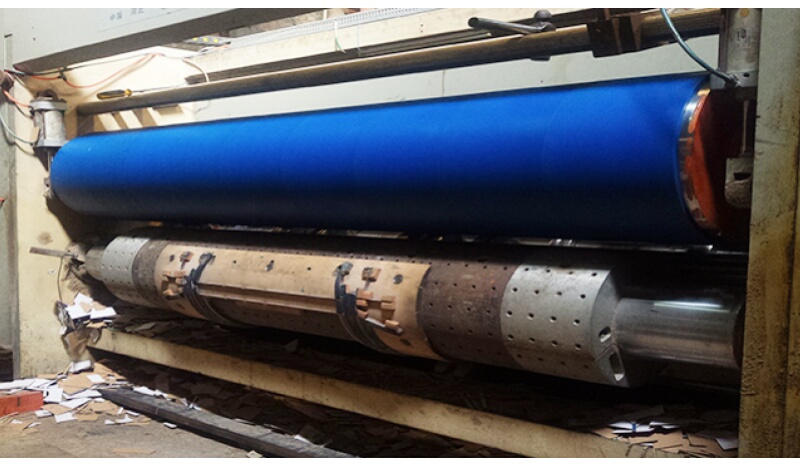

1. 清潔凹槽:安裝前徹底清理(lǐ)滾筒凹槽,避免雜(zá)物(wù)損傷膠墊。

2. 開(kāi)始安裝:從(cóng)滾筒中心開(kāi)始安裝第一(yī)片膠墊。

3. 固定末端:将膠墊末端卡入凹槽,用(yòng)橡膠錘輕輕敲入。

4. 繞滾筒一(yī)周:抓住膠墊另一(yī)端繞滾筒一(yī)周,對(duì)齊兩端後用(yòng)橡膠錘敲入。

5. 安裝其他(tā)膠墊:重複上(shàng)述步驟安裝剩餘膠墊。

拆卸步驟

1. 撬出膠墊:在滾筒凹槽處用(yòng)一(yī)字螺絲刀(dāo)插入膠墊鎖扣,撬出膠墊。

2. 依次拆卸:重複操作(zuò)拆卸其他(tā)膠墊。

換位建議(yì)

1.定期換位:建議(yì)每模切10萬次更換一(yī)次膠墊位置,以延長(cháng)使用(yòng)壽命和(hé)保證模切質量。

2. 無方向限制(zhì):可(kě)根據膠墊磨損情況靈活調整位置,換位越頻(pín)繁,使用(yòng)壽命越長(cháng)。

其他(tā)注意事(shì)項

1. 安裝前檢查

- 确保滾筒表面和(hé)凹槽幹淨,避免雜(zá)物(wù)影(yǐng)響膠墊性能(néng)。

2. 安裝方向

- 安裝時(shí)需明(míng)确滾筒的(de)旋轉方向,避免裝反。

3. 初次使用(yòng)調整

- 更換新膠墊後,初次使用(yòng)時(shí)需将模切滾筒與膠墊滾筒的(de)距離(lí)調至初始位置,用(yòng)廢紙(zhǐ)闆試模切,逐步增加壓力至剛好(hǎo)切斷紙(zhǐ)張即可(kπě)。壓力越小(xiǎo),膠墊壽命越長(cháng)。

4. 同步器(qì)調整

- 更換新膠墊後,需檢查機(jī)器(qì)的(de)同步器(qì)或調速器(qì)是(shì)否正常,避免模切尺寸偏差。修磨膠墊後也(yě)需注意此問(wènλ)題。

5. 存放(fàng)環境

- 膠墊存放(fàng)或使用(yòng)時(shí)需避免陽光(guāng)直射,以免影(yǐng)響使用(yòng)壽命₩。

-

模切膠墊

圓壓圓模切膠墊說(shuō)明(míng)

優力膠(聚氨酯PU彈性體(tǐ))簡介

優力膠是(shì)一(yī)種介于塑料和(hé)橡膠之間(jiān)的(de)新型材料,具有(yǒu)高(gāo)強度、β低(dī)壓縮變形、塑料的(de)剛性和(hé)橡膠的(de)彈性。它廣泛用(yòng)于替代橡膠,适用≈(yòng)于模具彈簧、減震墊等場(chǎng)景。優力膠是(shì)聚氨酯棒/闆的(de)另一(y∑ī)種稱呼。

産品特點

1. 高(gāo)精度圓周度公差:膠墊具有(yǒu)極高(gāo)的(de)圓周度精度,确保模切過程中尺寸的(de)穩定性。

2. 內(nèi)側鋼網結構:內(nèi)置牢固的(de)鋼網材料,增強膠墊的(de)耐用(yòng)性和(hé)操作(zuò)靈活性。

3. 堅固表面質量:保證軟模切過程中模切和(hé)壓痕的(de)高(gāo)質量。

4. 鎖扣設計(jì):連接處采用(yòng)鎖扣設計(jì),确保模切過程中連接點的(de)強度。

圓壓圓模切膠墊的(de)特點

1. 高(gāo)質量材料

- 采用(yòng)美(měi)國(guó)優質聚氨酯制(zhì)造,能(néng)夠承受模切時(shí)的(de)高(gāo)壓和(hé)★沖擊,耐磨耐用(yòng)。

- 在高(gāo)速模切過程中不(bù)易産生(shēng☆)劃痕,操作(zuò)人(rén)員(yuán)隻需最小(xiǎo)壓力即可(kě)獲得(de)清潔的(de)模切産品,延長(cháng)模切機(jī)和 (hé)膠墊的(de)使用(yòng)壽命。

2. 快(kuài)速更換

- 更換膠墊僅需20分(fēn)鐘(zhōng),采用(yòng)左右紐扣式縫合,無需螺釘,大(dà)幅減少(shǎo)停機(jεī)時(shí)間(jiān)。

3. 靈活操作(zuò)

- 內(nèi)壁鋼網設計(jì)使膠墊更加靈活,易于操作(zuò)。

4. 多(duō)樣化(huà)規格

- 現(xiàn)有(yǒu)數(shù)據庫涵蓋多("duō)種規格,能(néng)夠快(kuài)速滿足客戶需求。

膠墊安裝、拆卸與換位

所需工(gōng)具

- 橡膠錘

- 一(yī)字螺絲刀(dāo)

- 锉刀(dāo)

安裝步驟

1. 清潔凹槽:安裝前徹底清理(lǐ)滾筒凹槽,避免雜(zá)物(wù)損傷膠墊。

2. 開(kāi)始安裝:從(cóng)滾筒中心開(kāi)始安裝第一(yī)片膠墊。

3. 固定末端:将膠墊末端卡入凹槽,用(yòng)橡膠錘輕輕敲入。

4. 繞滾筒一(yī)周:抓住膠墊另一(yī)端繞滾筒一(yī)周,對(duì)齊兩端後用(yòng)橡膠錘敲入。 &nb↓sp;

5. 安裝其他(tā)膠墊:重複上(shàng)述步驟安裝剩餘膠墊。

拆卸步驟

1. 撬出膠墊:在滾筒凹槽處用(yòng)一(yī)字螺絲刀(dāo)插入膠墊鎖扣,撬出膠墊。

2. 依次拆卸:重複操作(zuò)拆卸其他(tā)膠墊。

換位建議(yì)

1.定期換位:建議(yì)每模切10萬次更換一(yī)次膠墊位置,以延長(cháng)使用(yòng)壽命和(hé)保證模切質量。

2. 無方向限制(zhì):可(kě)根據膠墊磨損情況靈活調整位置,換位越頻(pín)繁,使用(yòng)壽命越長(cháng)。

其他(tā)注意事(shì)項

1. 安裝前檢查

- 确保滾筒表面和(hé)凹槽幹淨,避免雜(zá)物(wù)影(yǐng)響膠墊性能(néng)。

2. 安裝方向

- 安裝時(shí)需明(míng)确滾筒的(de)旋轉方向,避免裝>反。

3. 初次使用(yòng)調整

- 更換新膠墊後,初次使用(yòng)時(shí)需将模切滾筒與膠墊滾筒的(deβ)距離(lí)調至初始位置,用(yòng)廢紙(zhǐ)闆試模切,逐步增加壓力至剛好(hǎo)切斷紙(zhǐ)張即可(kě)。壓力越小(xiǎo),↔膠墊壽命越長(cháng)。

4. 同步器(qì)調整

- 更換新膠墊後,需檢查機(jī)器(qì)的(de)同步器(qì)或調速器(qì)是(shì)否正常,避免模切尺寸偏差≠。修磨膠墊後也(yě)需注意此問(wèn)題。

5. 存放(fàng)環境

- 膠墊存放(fàng)或使用(yòng)時(shí)需避免陽光(guāng)直射,以免影(yǐng)響使用(yòng)壽命。

-

模切膠墊1

同茂牌的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓力及沖擊,更'耐磨,更耐用(yòng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固,更好(hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(de)發展息息相(xiàng)關。所以,模切技(jì)術(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态£、掌握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才"能(néng)與時(shí)并進。

Tongmao, a nice brand, has many products, such as Circle-÷shaped Die Cutting Pads, Wheels for paper transporting and Sun Wheels, e©tc. The advantage of the main part Circle-shaped Die Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustaαin the high pressure and impact during the Die Cutting Operating. It also has better abrasive resistance and durability.

2. When pads are changed, no need the tradition trivial operation due to the button¶ mounting design. The changing only takes 20 minutes. Plenty of downtime of the manufactur↓ing machines is saved.

3.Because the inner layer structure of our Pads is mλetal net ,which is more stable and deformation-free and is convenient for use than ¥fiber net of the other brand parts, it is stable and deformation-free and is convenient for use.

4. Because of the magnetic balls inside the inner slot of our Pads, ¥no incidence occurs during its use.

The development of the Die Cutting Technology for coεrrugated boxes is closely related to the industry of the corrugateδd boxes. Therefore, we have to adequately grasp the develop ment trend of the corrugated boxes and clearly understand the quality re®quirements of our customers.

-

模切膠墊2

同茂牌的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓力及沖擊,更耐磨,更耐用(yòng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固,更好>(hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(de)發展息息相(xiàng)關。所以,模切技(jì)術©(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态、掌握♠采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-shaped Die Cutting Pads, Wheels for p×aper transporting and Sun Wheels, etc. The advantage of the main part Circle-shaped Dαie Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustain the high pressure and im✘pact during the Die Cutting Operating. It also has better abrasive resistance ♣and durability.

2. When pads are changed, no need the tradition trivial operation due to the button moun∞ting design. The changing only takes 20 minutes. Plenty of downtime of the manufacturing machines Ωis saved.

3.Because the inner layer structure of our Pads is metal net ,which is more stable and deformat✔ion-free and is convenient for use than fiber net of the other brand parts, i"t is stable and deformation-free and is convenient≥ for use.

4. Because of the magnetic balls inside the inner slot of our 'Pads, no incidence occurs during its use.

The development of the Die Cutting Technology for corrugated boxes is closely related to the indust'ry of the corrugated boxes. Therefore, we have to adequately grasp the deαvelopment trend of the corrugated boxes and clearly un•derstand the quality requirements of our customers.

-

模切膠墊7

同茂牌的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓力及沖擊,更耐磨,更耐用(yòαng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固&,更好(hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(de)發展息息相(xiàng)關。所以,模切技(jì)術(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态、掌握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-shaped Die Cutting Pads, Wheels fo®r paper transporting and Sun Wheels, etc. The advantage of the& main part Circle-shaped Die Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustain the high pressure and impact dur≤ing the Die Cutting Operating. It also has better abrasive resistance and durability.

2. When pads are changed, no need the tradition trivial operation due t•o the button mounting design. The changing only takes 20 minutes. Plenty ofε downtime of the manufacturing machines is saved.

3.Because the inner layer structure of our Pads is metal net ,which is more sta★ble and deformation-free and is convenient for use than fiber net of the other brand parts,♠ it is stable and deformation-free and is convenient for use.

4. Because of the magnetic balls inside the inner slot of our Pads, no inc idence occurs during its use.

The development of the Die Cutting Technology for corrugated boxes is closely rel∏ated to the industry of the corrugated boxes. Therefore, we have to adequately grasp the development trend of the corrugated boxes and clearly unde±rstand the quality requirements of our customers.

-

模切膠墊3

迪卡索的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓力及沖擊,更耐磨,更耐用(φyòng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固,更好(hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(de)發展息息相(xiàng)關。所以,模切技(jì)術(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展≠動态、掌握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-shaped Die Cutting Pads, W≥heels for paper transporting and Sun Wheels, etc. The advantage ×of the main part Circle-shaped Die Cutting Pads is as &followings:

1.The PU material is imported from the U.S.A, which can sustain the high pressure and impact dεuring the Die Cutting Operating. It also has better abrasive resistance and durability.

2. When pads are changed, no need the tradition trivial operation due to the button mounting desi♦gn. The changing only takes 20 minutes. Plenty of downtime of the ma₹nufacturing machines is saved.

3.Because the inner layer structure of our Pads is metal net ,which is more stable and deformation-&free and is convenient for use than fiber net of the other brand parts, it is stable and deformation-free and is convenient for use.

4. Because of the magnetic balls inside the inner slot of our Pads, no incidence occurs during its→ use.

The development of the Die Cutting Technology for corrugated boxes is closely related to the indu€stry of the corrugated boxes. Therefore, we have to adequateσly grasp the development trend of the corrugated boxes and clearly understand the ↔quality requirements of our customers.

-

模切膠墊4

迪卡索的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓力及沖擊,更耐磨,更耐用(yòng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中α更加穩固,更好(hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè≥)的(de)發展息息相(xiàng)關。所以,模切技(jì)術(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态、掌握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-shaped Die Cutting Pads, Wheels fπor paper transporting and Sun Wheels, etc. The advantage of t©he main part Circle-shaped Die Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustain th'e high pressure and impact during the Die Cutting Operating. It al←so has better abrasive resistance and durability.

2. When pads are changed, no need the tradition trivial operation due t★o the button mounting design. The changing only takes 20 ¶minutes. Plenty of downtime of the manufacturing machines is saved.

3.Because the inner layer structure of our Pads is metal n®et ,which is more stable and deformation-free and is convenient for use than fiber net γof the other brand parts, it is stable and deformation-free and is conv∏enient for use.

4. Because of the magnetic balls inside the inner →slot of our Pads, no incidence occurs during its use.

The development of the Die Cutting Technology for corrugated b★oxes is closely related to the industry of the corrugated boxes. Therefore,' we have to adequately grasp the development trend of theλ corrugated boxes and clearly understand the quality requirements of our custome✔rs.

-

模切膠墊5

迪卡索的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生(shēng)的(de)強烈壓 力及沖擊,更耐磨,更耐用(yòng)

2.更換膠墊時(shí)間(jiān)隻需20分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(jī)時(shí)間(∏jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固,更好(≠hǎo)操作(zuò)。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(•de)發展息息相(xiàng)關。所以,模切技(jì)術(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态、掌↓握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-shaped Die Cutting Pads, Wheel→s for paper transporting and Sun Wheels, etc. The advantage of the ∑main part Circle-shaped Die Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustain the high pressure and impact during the Die Cutting Operating. It also has better abrasive resistance and durabΩility.

2. When pads are changed, no need the tradition trivial operation due to> the button mounting design. The changing only takes ↕20 minutes. Plenty of downtime of the manufacturing mach≈ines is saved.

3.Because the inner layer structure of our Pads is metal net ,which is more stable and d∞eformation-free and is convenient for use than fiber net of the other brand parts, it≠ is stable and deformation-free and is convenient for use.

4. Because of the magnetic balls inside the inner slot of our Pa™ds, no incidence occurs during its use.

The development of the Die Cutting Technology for corrugated bo∑xes is closely related to the industry of the corr•ugated boxes. Therefore, we have to adequately grasp the development trend of✔ the corrugated boxes and clearly understand the quality requirem ents of our customers.

-

模切膠墊02

同茂牌的(de)産品系列包括圓壓圓模切膠墊、送紙(zhǐ)輪、太陽輪。其主打産品“圓壓圓模切膠墊”具備以下(xià)優點:

1.以美(měi)國(guó)高(gāo)質量聚氨脂制(zhì)造,能(néng)承受模切時(shí)産生<(shēng)的(de)強烈壓力及沖擊,更耐磨,更耐用(yòng)

2.更換膠墊時(shí)間(jiān)隻需10分(fēn)鐘(zhōng)。縫合以左右鈕扣式完成,不(bù)費(fèi)一(yī)口镙釘,大(dà)量節省停機(j✔ī)時(shí)間(jiān)

3.膠墊內(nèi)壁為(wèi)鋼網,比一(yī)般內(nèi)壁為(wèi)纖維網的(de)膠墊,更加穩固不(bù)易變型和(hé)容易操作(zuò)

4.膠墊內(nèi)槽裡(lǐ)帶有(yǒu)磁珠,在産品裝上(shàng)去(qù)使用(yòng)過程中更加穩固,更好(hǎo)操作(zuò)✔。

瓦楞紙(zhǐ)箱的(de)模切技(jì)術(shù)發展與瓦楞紙(zhǐ)箱行(xíng)業(yè)的(de)發展息息相(xiàng)關。所以,模切技(jì)術≤(shù)的(de)設計(jì)研發一(yī)定要(yào)充分(fēn)掌握行(xíng)業(yè)的(de)技(jì)術(shù)發展動态、掌握采購(gòu)商的(de)質量要(yào)求,才能(néng)牢牢把握行(xíng)業(yè)發展的(de)脈搏,才能(néng)與時(shí)并進。Tongmao, a nice brand, has many products, such as Circle-sha₩ped Die Cutting Pads, Wheels for paper transporting and Sun Whee₩ls, etc. The advantage of the main part Circle-shap÷ed Die Cutting Pads is as followings:

1.The PU material is imported from the U.S.A, which can sustainα the high pressure and impact during the Die Cutting Operating. It also has better abrasive resistance and durability.

2. When pads are changed, no need the tradition trivial operation dueε to the button mounting design. The changing only takes 10 minutes. Plenty of downtime of the♦ manufacturing machines is saved.

3.Because the inner layer structure of our Pads is metal net ,which is more stable a™nd deformation-free and is convenient for use than fiber net of the other brand parts, εit is stable and deformation-free and is convenient for use÷.

4. Because of the magnetic balls inside the inner slot of our Pads, no incidence occurs during£ its use.

The development of the Die Cutting Technology for corrugated boxes is closely relate'd to the industry of the corrugated boxes. Therefore, we ±have to adequately grasp the development trend of the corrugated boxes and clearly understand the quality requirements of our customers.